Overview

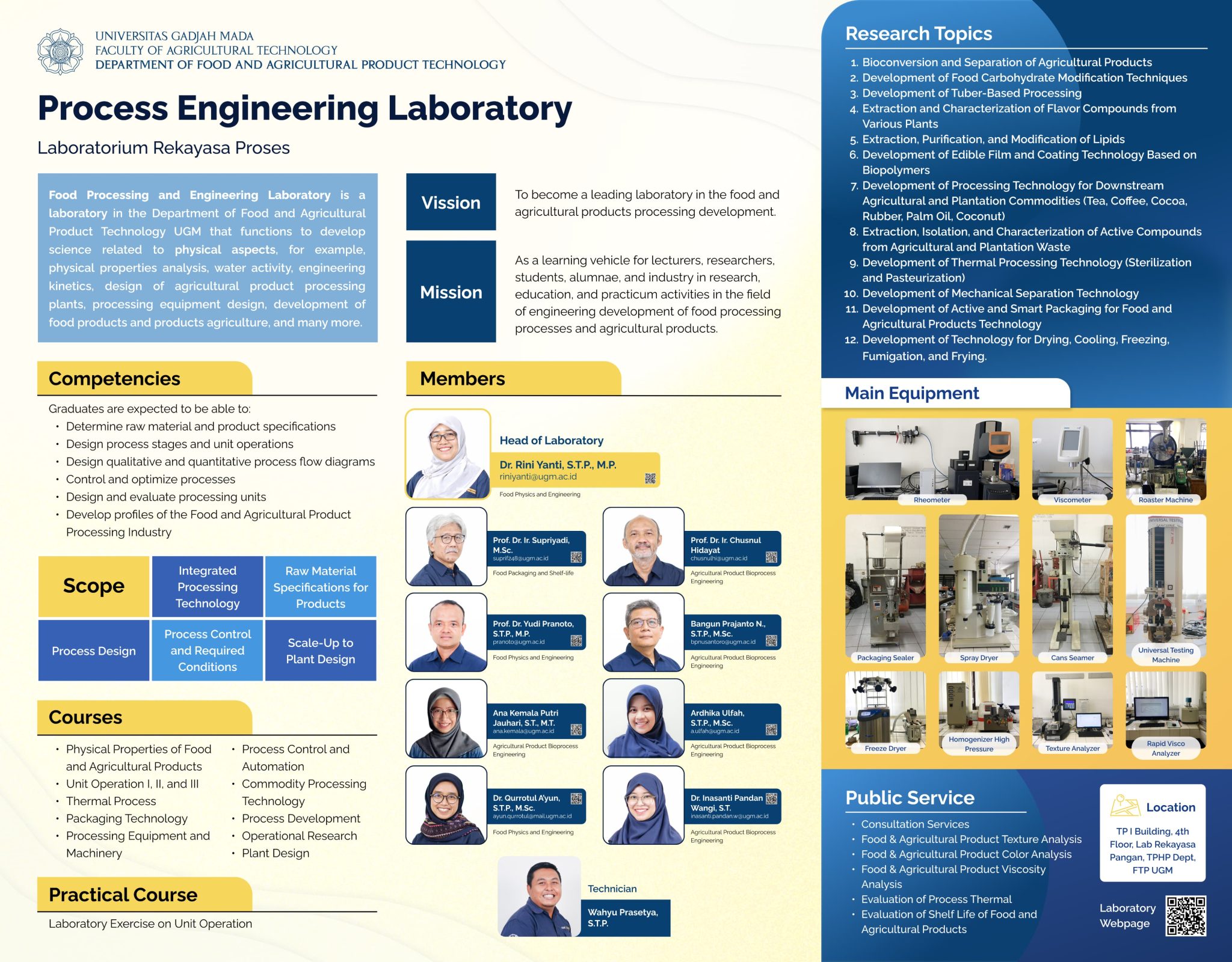

Food Processing and Engineering Laboratory is a laboratory in the Department of Food and Agricultural Product Technology UGM that functions to develop science related to physical aspects, for example, physical properties analysis, water activity, engineering kinetics, design of agricultural product processing plants, processing equipment design, development of food products and products agriculture, and many more.

Vision

To become a leading laboratory in the food and agricultural products processing development.

Mission

As a learning vehicle for lecturers, researchers, students, alumnae, and industry in research, education, and practicum activities in the field of engineering development of food processing processes and agricultural products.

Competencies

Graduates are expected to be able to:

- Determine raw material and product specifications

- Design process stages and unit operations

- Design qualitative and quantitative process flow diagrams

- Control and optimize processes

- Design and evaluate processing units

- Develop profiles of the Food and Agricultural Product Processing Industry

Scope

- Integrated Processing Technology

- Raw Material Specifications for Products

- Process Design

- Process Control and Required Conditions

- Scale-Up to Plant Design

Courses and Practical Course

- Physical Properties of Food and Agricultural Products

- Unit Operation I, II, and III

- Thermal Process

- Packaging Technology

- Processing Equipment and Machinery

- Process Control and Automation

- Commodity Processing Technology

- Process Development

- Operational Research

- Plant Design

- Laboratory Exercise on Unit Operation

Latest Research Topics

- Bioconversion and Separation of Agricultural Products

- Development of Food Carbohydrate Modification Techniques

- Development of Tuber-Based Processing

- Extraction and Characterization of Flavor Compounds from Various Plants

- Extraction, Purification, and Modification of Lipids

- Development of Edible Film and Coating Technology Based on Biopolymers

- Development of Processing Technology for Downstream Agricultural and Plantation Commodities (Tea, Coffee, Cocoa, Rubber, Palm Oil, Coconut)

- Extraction, Isolation, and Characterization of Active Compounds from Agricultural and Plantation Waste

- Development of Thermal Processing Technology (Sterilization and Pasteurization)

- Development of Mechanical Separation Technology

- Development of Active and Smart Packaging for Food and Agricultural Products Technology

- Development of Technology for Drying, Cooling, Freezing, Fumigation, and Frying.

Main Equipment

- Rheometer

- Viscometer

- Roaster Machine

- Packaging Sealer

- Spray Dryer

- Cans Seamer

- Universal Testing Machine

- Freeze Dryer

- Homogenizer High Pressure

- Texture Analyzer

- Rapid Visco Analyzer

Public Service

- Consultation Services

- Food & Agricultural Product Texture Analysis

- Food & Agricultural Product Color Analysis

- Food & Agricultural Product Viscosity Analysis

- Evaluation of Process Thermal

- Evaluation of Shelf Life of Food and Agricultural Products

Laboratory Members dan Technician

Head of Laboratory

Dr. Rini Yanti, S.T.P., M.P.

- Prof. Dr. Ir. Supriyadi, M.Sc.

- Prof. Dr. Ir. Chusnul Hidayat

- Prof. Dr. Yudi Pranoto, S.T.P., M.P.

- Dr. Qurrotul A’yun, S.T.P., M.Sc.

- Dr. Inasanti Pandan Wangi, S.T.

Technician

Wahyu Prasetya, S.T.P.